Roll Form Machines in Turkey

Advanced Technology, Maximum Efficiency, High Energy Savings

We specialize in crafting Roll Forming systems tailored to meet your unique production needs. We design and manufacture integrated Roll Forming processes to ensure optimal performance.

Our core mission is to create user-friendly, high-quality machines customized to your specific requirements.

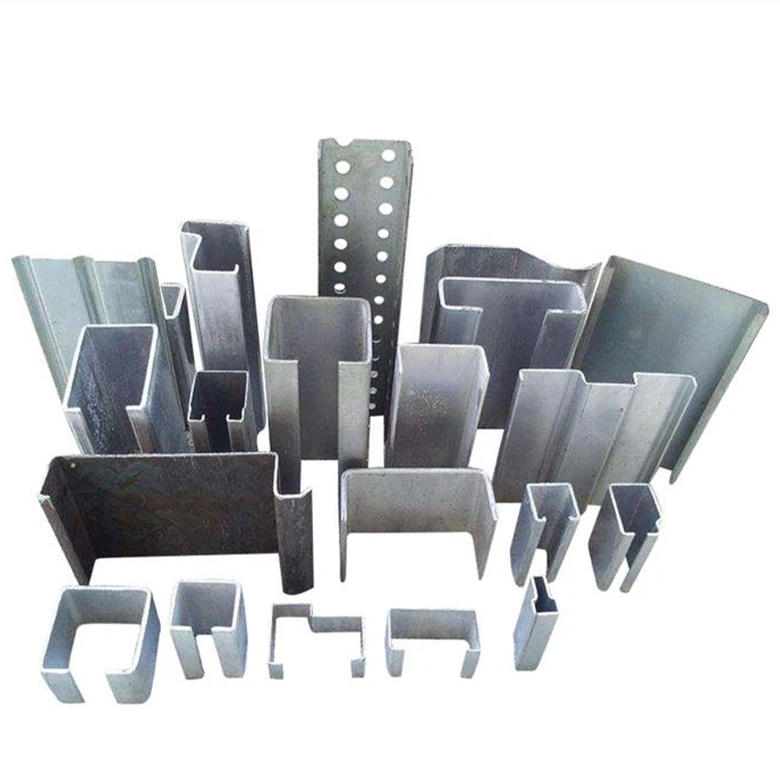

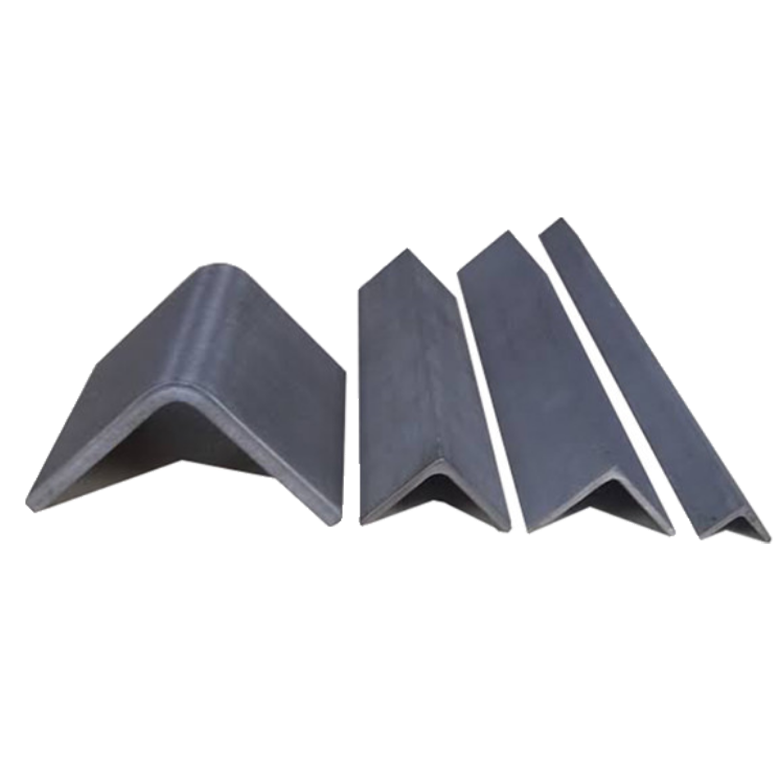

We offer cutting-edge technological solutions for profile and finished product manufacturing across diverse sectors, including:

- Automotive

- Logistics

- Construction

- Energy

- Agriculture

- Lighting

- Shelving, and more.

With Interberk, you get tailored solutions that drive innovation and efficiency in every project.

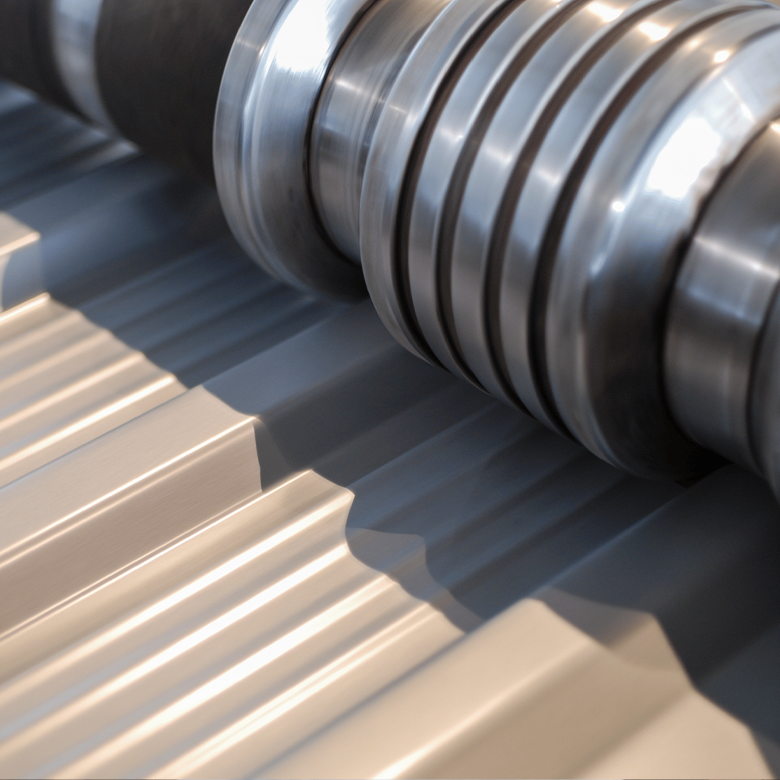

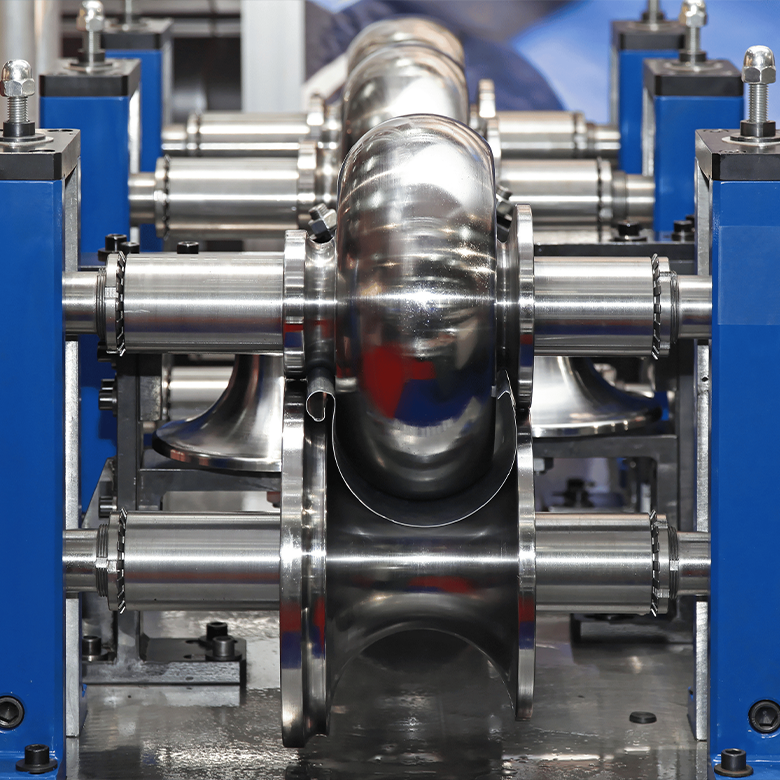

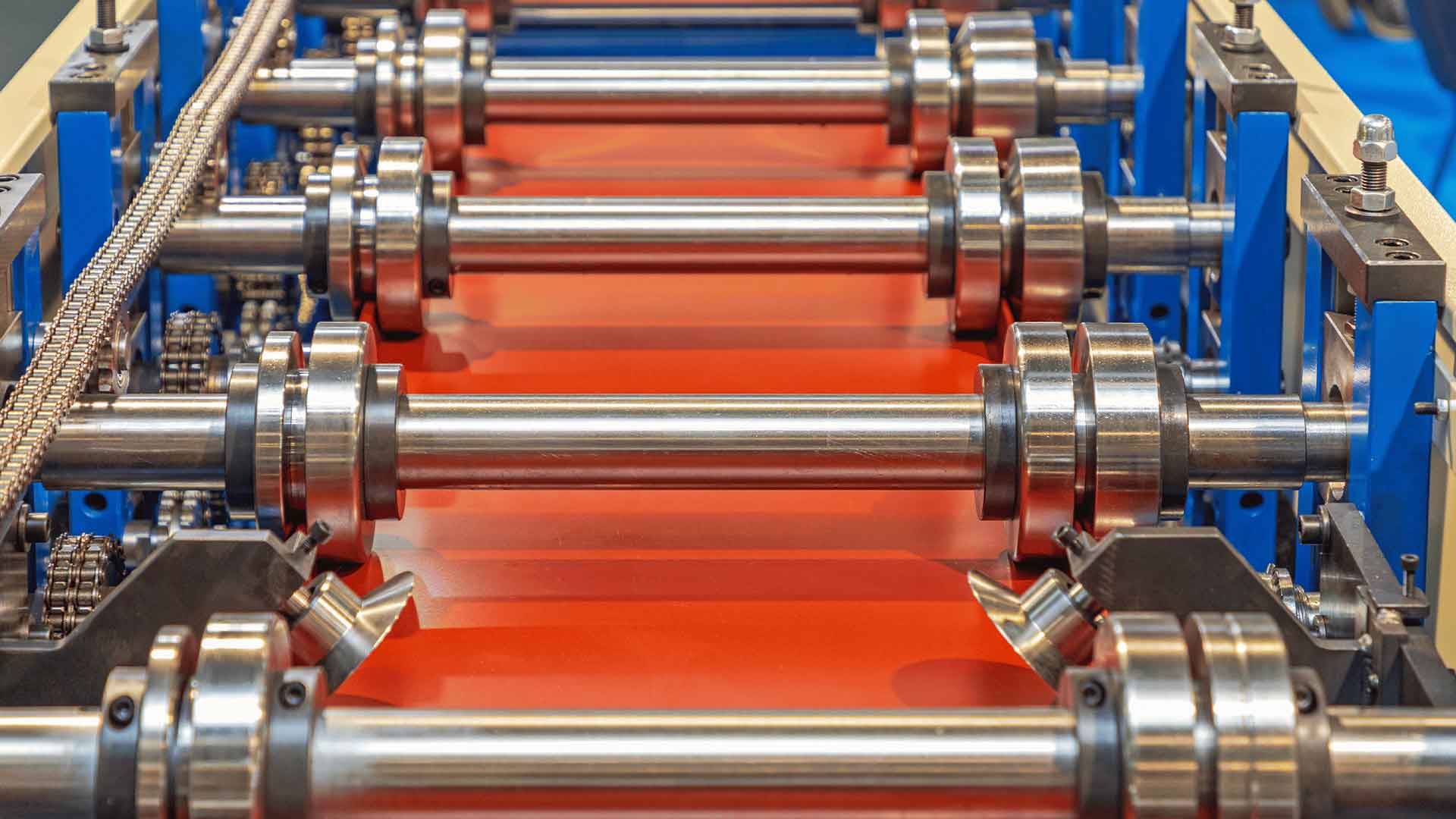

Roll Forming Machine

Cutting-Edge Techniques for Every Profile

Our advanced machinery lines can handle profiles with thicknesses ranging from 0.2 mm to 6.0 mm, making us a versatile partner for various industries and applications.

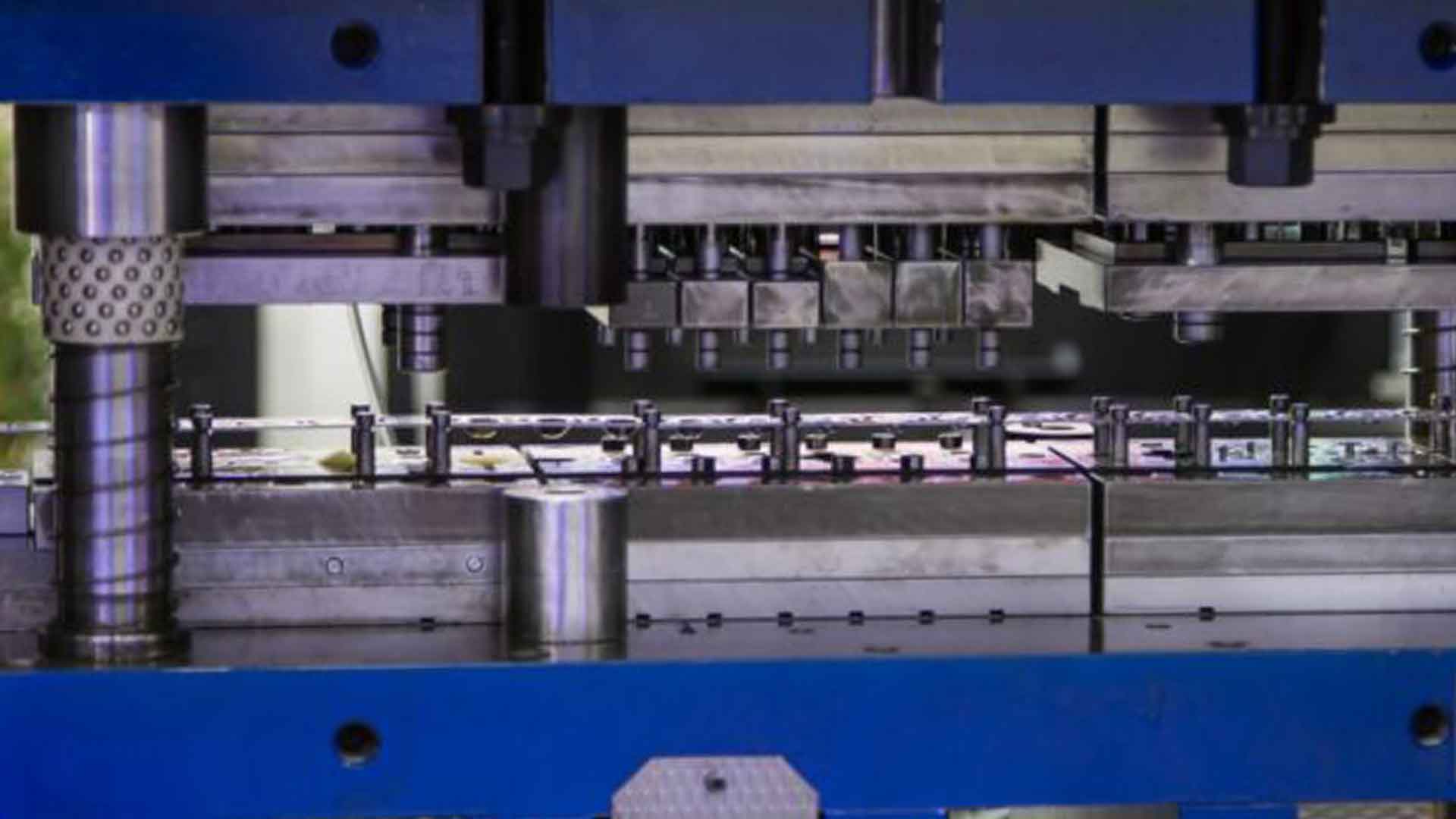

Efficiency

The combination of maximum production performance and process reliability offers optimum efficiency. With aour roll forming machine, you'll quickly achieve your ROI, saving you both time and money.

Individuality

The individuality of your roll forming machine will impress you. It stands out because the profiles you manufacture are unique, and so is the machine that creates them.

Innovation

Our roll forming experts are constantly pushing the boundaries of technology to stay ahead. With our cutting-edge roll forming machines and systems, your products will not only meet but set the standards for innovation and excellence.

Industry Experts

Many of our employees have been with us for years, giving them unmatched insider knowledge. They can swiftly understand the precise requirements for manufacturing your profiles, ensuring expert attention to detail.

OUR CLIENTS

They already have trusted ESTECH

Vivamus in diam turpis. In condimentum maximus tristique. Maecenas non laoreet odio. Fusce lobortis porttitor purus, vel vestibulum libero pharetra vel.

Mark Spencer

Lorem ipsum dolor

Vivamus in diam turpis. In condimentum maximus tristique. Maecenas non laoreet odio. Fusce lobortis porttitor purus, vel vestibulum libero pharetra vel.

Mark Spencer

Lorem ipsum dolor

Vivamus in diam turpis. In condimentum maximus tristique. Maecenas non laoreet odio. Fusce lobortis porttitor purus, vel vestibulum libero pharetra vel.

Mark Spencer

Lorem ipsum dolor