Metal Forming 101

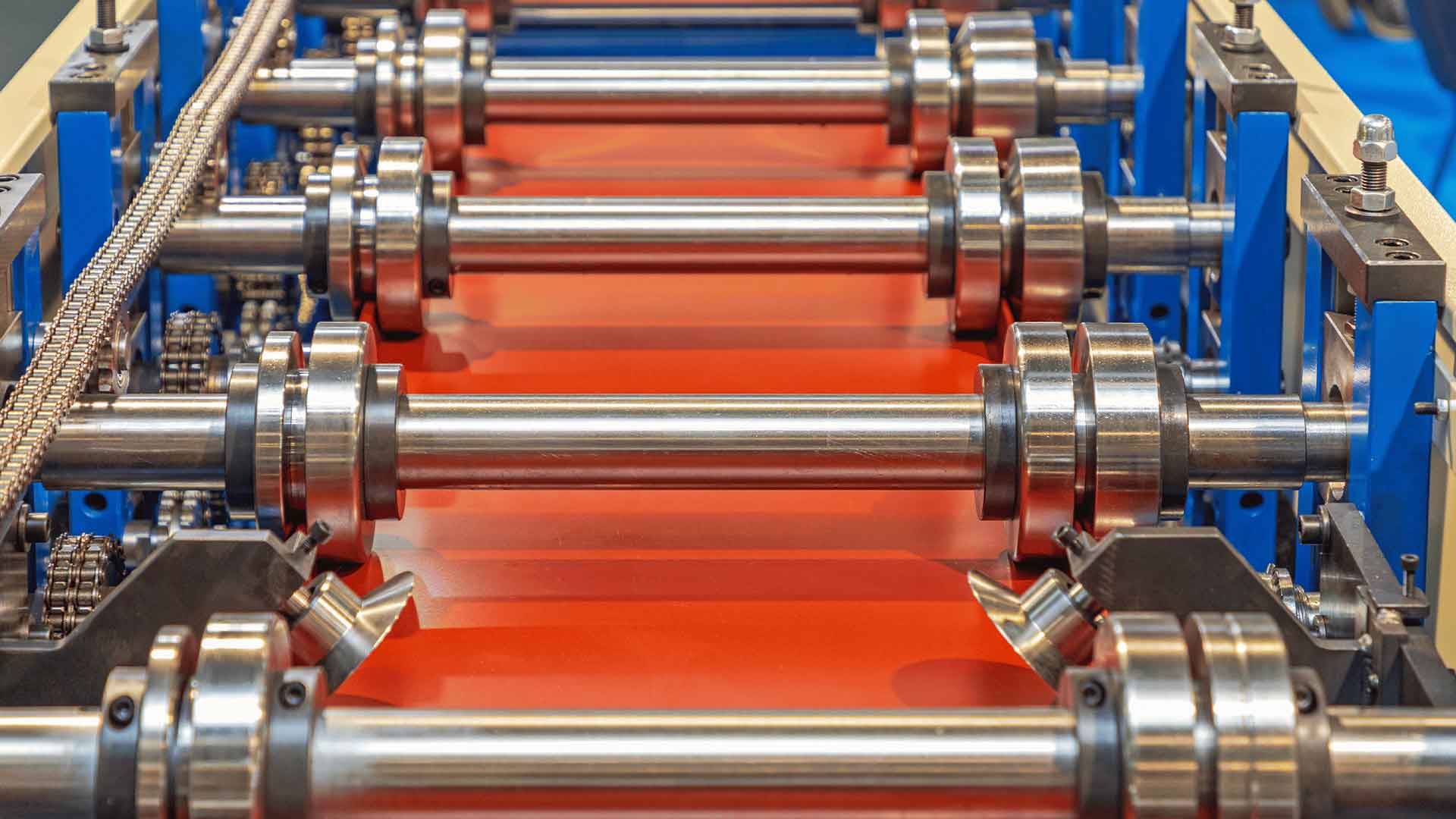

Roll Forming Technology

When searching for a manufacturing partner capable of producing large quantities of products, efficiency and communication are key factors. While many companies might think that a large roll forming partner is necessary to meet these needs, working with a small or mid-sized metal roll forming company can actually offer significant advantages. Here’s why partnering with a smaller roll former could be the best decision for your business.

The Benefits of Partnering with a Smaller Roll Former

High Standards Comparable to Larger Manufacturers

- Smaller roll forming companies can match the quality and standards of their larger counterparts if they invest wisely. Many of these companies are ISO-certified and employ advanced metal roll forming machines that produce shapes for top manufacturers worldwide. Unlike larger suppliers, a small or mid-sized roll former can focus on delivering excellent results for a select group of clients, ensuring that quality remains consistently high.

Custom Vendor-Managed Inventory Systems

- One of the major benefits of working with a smaller roll former is the ability to establish a close, long-term relationship. This partnership allows for a more personalized approach to inventory management. A custom vendor-managed inventory system, rooted in just-in-time (JIT) delivery and pull system concepts, can reduce your inventory investment, lower administrative costs, free up space, and improve logistics management. Your roll forming partner will have the time and expertise to monitor market trends, ensuring you get the best prices for raw materials.

A Dynamic In-House Engineering Team

- The design of your roll-formed components impacts costs, lead times, and product quality. A smaller roll forming company with a dynamic in-house engineering team can work closely with you to optimize your product design. This close collaboration can help you avoid common pitfalls and ensure that your products are not only efficient to produce but also cost-effective.

- Access to Reliable Tools

- Precision metal manufacturing often requires custom tools, which can be a significant investment. However, a small or mid-sized roll former might already have an extensive collection of tools at their disposal, available for your use at no additional cost.

Tips for a Successful Partnership with a Metal Roll Former

Working with a metal roll forming partner can greatly benefit your business, especially when you establish a strong, flexible partnership. Here are some tips to ensure a happy and productive collaboration with your roll forming partner:

1. Prioritize Flexibility

Your metal roll forming partner should be adaptable and ready to meet your evolving needs. Flexibility in production processes, design adjustments, and scheduling can help ensure that your project stays on track, even when unexpected changes occur.

2. Establish a Supply Agreement

Creating a supply agreement with your roll forming collaborator is crucial for mutual understanding. This agreement should clearly outline the specifications, processes, and expectations for both parties. The benefits of such an agreement include:

- Cost Savings: By clearly defining expectations and processes, you can avoid costly misunderstandings and delays.

- Reliability: A supply agreement ensures that both parties are aligned, leading to consistent and reliable production.

- Clarity: Knowing the specifications and requirements of your supply system helps prevent errors and ensures smooth operations.

Conclusion

Partnering with a small or mid-sized metal roll forming company can provide your business with the same high standards, if not higher, than those of larger manufacturers. With custom inventory management, a dedicated engineering team, and access to existing tools, these companies can offer a level of personalized service and cost savings that larger firms may not be able to match. If you’re looking for a reliable partner to help boost your business, consider the advantages of working with a smaller roll former. It might be the big boost your business needs.