Why a Small Metal Roll Forming Partner Can Be a Big Boost for Your Business

The Value Es-Tech’s Customized Machinery Solutions Will Add to Your Business

Efficiency and Innovation in Metal Forming with Roll Forming Technology

Metal forming plays a critical role in industrial production. The efficiency of the machines used in this process directly affects the quality of the final product. Traditional metal forming methods are often associated with high costs and lengthy production times. However, advancements in technology in recent years have introduced revolutionary solutions in this field. One of these innovative solutions is Roll Forming machines.

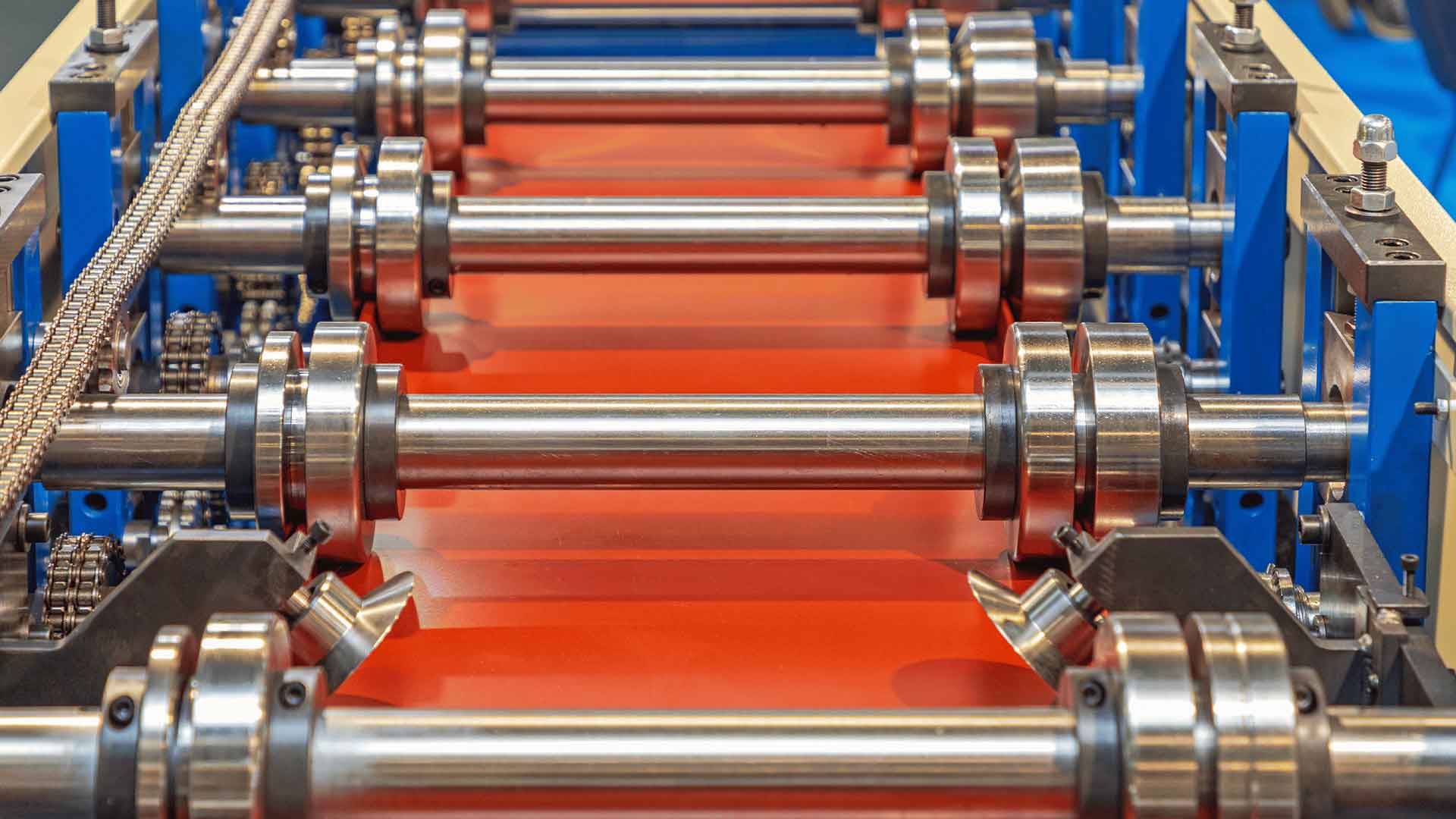

Fundamental Principles of Roll Forming Technology

Roll Forming is a technology used for continuously shaping metal sheets. In this process, metal sheets are passed through a series of rollers and are gradually shaped step by step until the desired form is achieved. Roll Forming machines offer high precision, particularly in the production of parts with long and complex cross-sections. These machines enable the metal to be formed quickly and efficiently, with minimal waste.

Advantages Over Traditional Methods

Roll Forming machines have several advantages compared to traditional pressing or bending methods:

High Speed and Efficiency

- The continuous production process allows for large quantities to be produced at much faster rates.

Less Material Waste:

- Minimal cutting and waste are produced as the material takes its desired shape.

Low Energy Consumption:

- Roll Forming uses less energy compared to traditional methods, reducing production costs.

Wide Range of Applications:

- It is widely used in industries such as construction, automotive, and home appliances.

Next-Generation Solutions and Future Perspectives

Technological advancements have also spurred the development of Roll Forming machines. Automation systems make it possible for machines to operate with minimal human intervention, allowing for the easy production of more complex shapes. Additionally, these advancements increase energy efficiency, making Roll Forming machines a preferred choice for environmentally friendly production. Technologies that support sustainable production further enhance the appeal of Roll Forming machines.

Conclusion

Roll Forming machines represent a major revolution in metal forming technology. With advantages such as high speed, low cost, and efficiency, these machines optimize production processes and have become essential in many industries. Equipped with features like automation and energy efficiency through technological innovation, Roll Forming machines contribute to the goals of sustainable production.

In the future, Roll Forming machines are expected to evolve further and become a standard solution in various industrial sectors. By investing in Roll Forming technology, businesses can gain a competitive advantage and increase their production capacity. In conclusion, Roll Forming machines will continue to offer next-generation solutions for metal forming processes and play a vital role in industrial production.