Understanding Punch Press:

Why a Small Metal Roll Forming Partner Can Be a Big Boost for Your Business

Metal forming is a cornerstone of the steel processing industry, known for its ability to mold complex shapes and structures. This process is widely embraced across North America, essential in producing a vast range of products—from precision automotive parts to critical aerospace components. The success of metal forming hinges on the expertise of skilled professionals and the use of advanced machinery, often found at specialized steel service centers. These centers are vital, transforming raw materials into finished products and playing a key role in the supply chain.

What is Metal Forming?

Metal forming is the art of shaping a piece of metal into a desired form using various techniques. This process is crucial in manufacturing, allowing the creation of metal parts in various shapes and sizes. Whether it’s roll forming, bending, extrusion, or forging, metal forming is a highly efficient and precise method that has become indispensable in today’s manufacturing industry.

The Metal Forming Process: An Overview

Metal forming encompasses a wide range of techniques, each suited to different applications. These methods include:

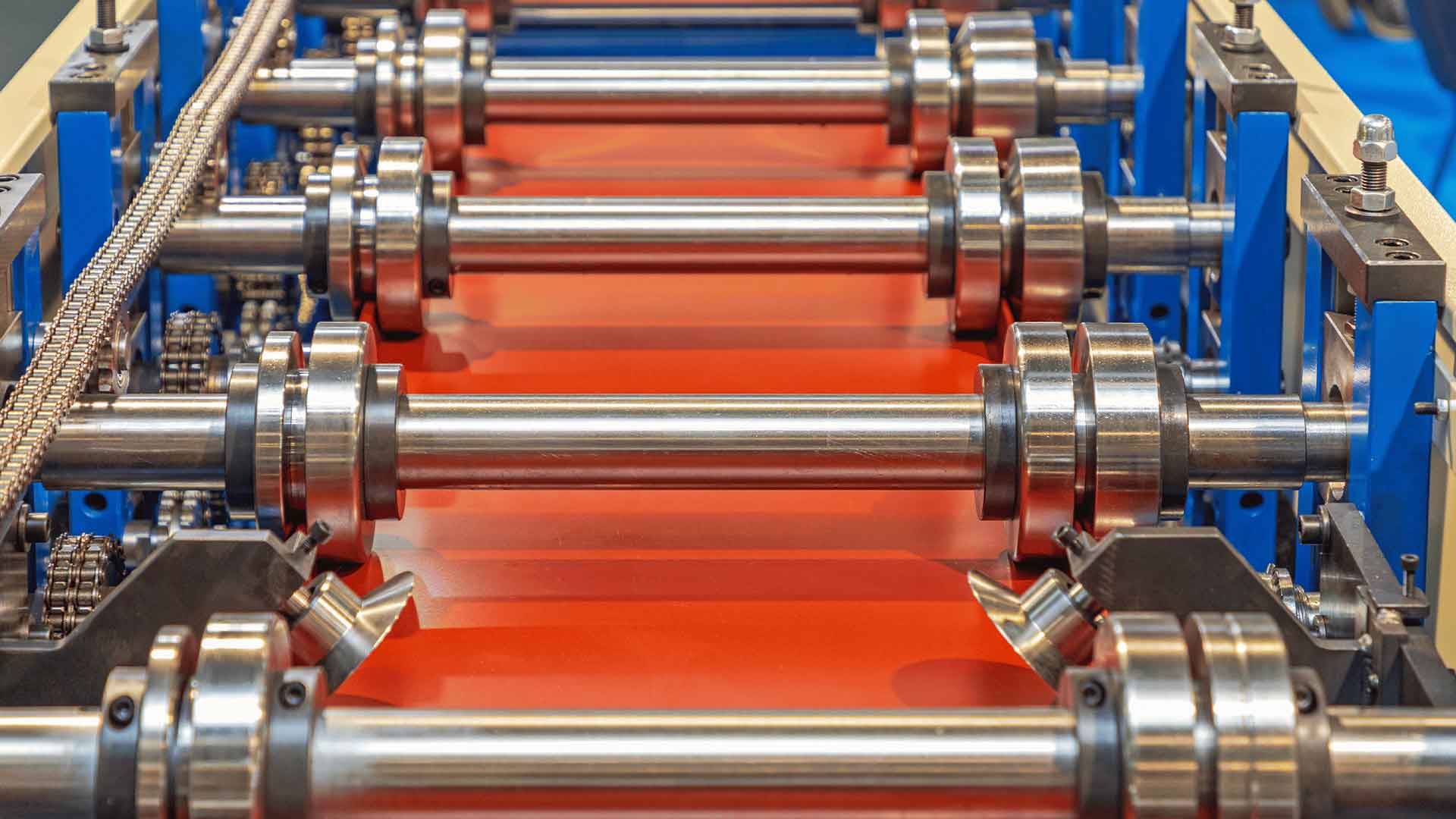

- Roll Forming: A process where a long strip of metal, typically coiled steel, is passed through consecutive sets of rolls to achieve a specific cross-sectional profile. Roll forming is versatile and can produce various shapes and sizes at room temperature. It is particularly valued for its ability to create intricate geometries with high precision and minimal waste.

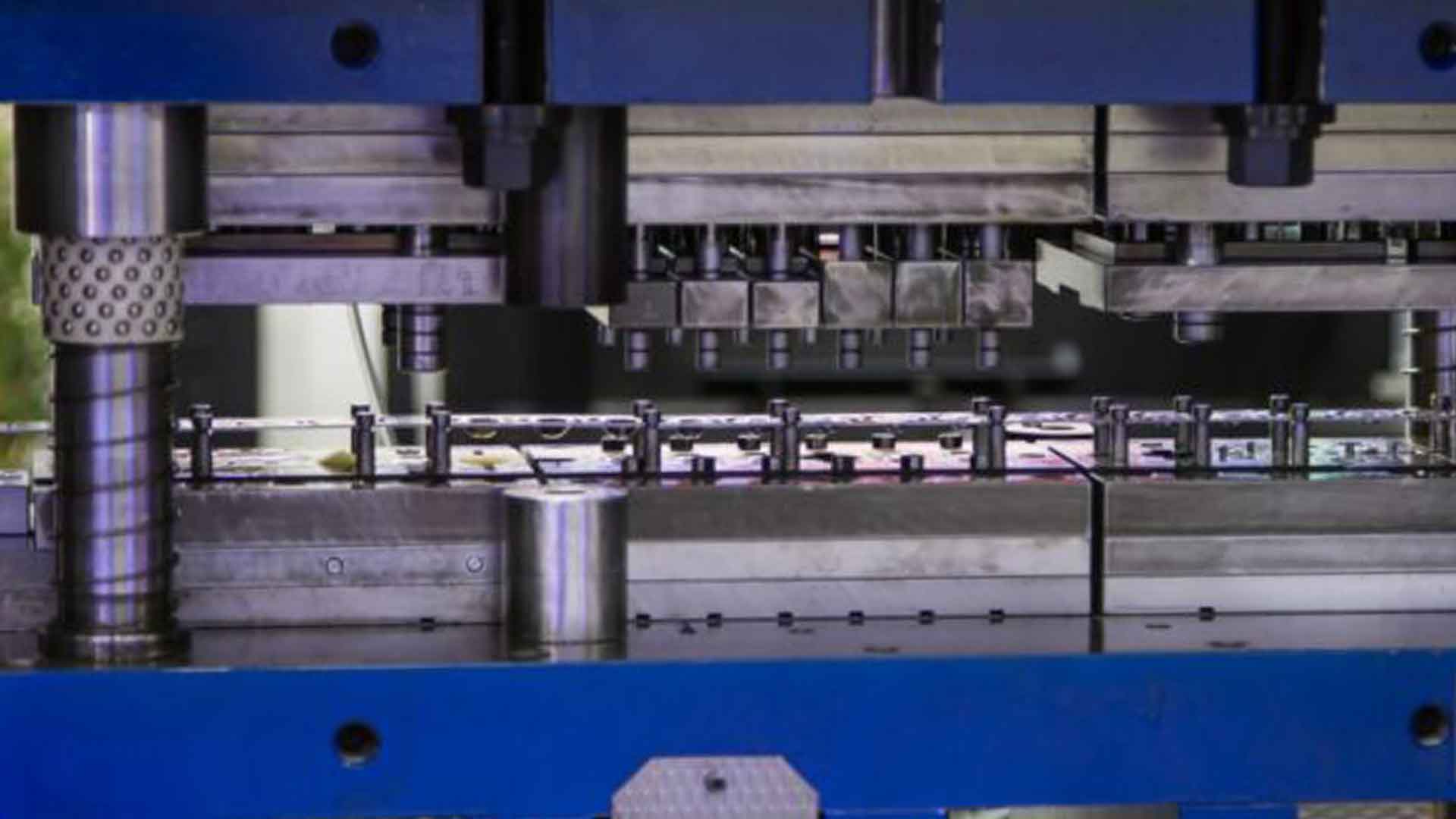

- Bending: This technique deforms metal by applying force, creating curves, corners, and other shapes. Bending is cost-effective and precise, making it a popular choice for forming metal parts with minimal tooling requirements.

- Extrusion: A process where metal is pushed through a die to create objects with a uniform cross-section. Extrusion is ideal for producing long, continuous lengths of material, such as pipes, tubing, and complex cross-sectional shapes.

- Forging: Involves shaping metal using compressive forces, either through hammering or die pressing. Forging can be done at different temperatures, each offering unique benefits, from increased toughness to reduced surface roughness.

- Deep Drawing: A method used to create three-dimensional shapes from sheet metal by pressing it into a die. This process is common in the automotive and aerospace industries, where high-quality, precision components are required.

Applications of Metal Forming

Metal forming is essential in various industries, with applications ranging from everyday items to critical industrial components:

- Automotive Industry: Metal forming is crucial in producing various car parts, from screws to body panels. The average car contains nearly 2,000 pounds of steel, much of which is shaped through metal forming processes.

- Aerospace Industry: Metal forming is vital in manufacturing high-quality aerospace components, including engine parts, landing gear, and structural elements. The precision and durability of metal forming are essential in this high-stakes industry.

- Pressure Vessels: These containers, designed to hold liquids or gases at high pressures, rely on metal forming to achieve the necessary strength and durability.

- Pipes and Tubes: Metal forming processes are used to produce various pipes and tubes, essential for transporting liquids and gases in numerous applications.

The Role of Metal Service Centers

In the competitive steel processing industry, metal service centers are key players. They provide essential services such as metal forming, processing, and distribution, helping customers across various industries meet their production needs. These centers ensure that raw materials are efficiently transformed into the high-quality products required in today’s market.

In summary, metal forming is a vital process in the steel industry, enabling the creation of a wide array of products with precision and efficiency. Whether for the automotive sector, aerospace industry, or other applications, metal forming is an indispensable part of modern manufacturing.