Industry 4.0

At ESTECH, we embarked on a digital transformation journey years ago, integrating the challenges and benefits of Industry 4.0 into our machinery. We continuously develop innovative solutions to enhance the productivity of your roll forming and processing lines.

Leveraging the latest technology development methods, our software solutions for real-time monitoring, predictive maintenance, and manufacturing tracking contribute to cost savings and increased profitability. By utilizing IIoT and AI technologies, we turn machine and sensor data into valuable insights.

With ESTECH’s new solutions, you can monitor and control all your machines and production processes through a single platform. This solution facilitates connecting your machinery to the cloud, allowing for the comprehensive collection and processing of all data.

If you want your field operators to interact more with real-time production data and report digitally, our ESTECH system is ideal. We offer conventional systems that provide screens accessible via any device (tablet, kiosk, etc.). Alternatively, we can integrate functionalities directly into your HMIs, eliminating the need for your operators to manage multiple screens/interfaces.

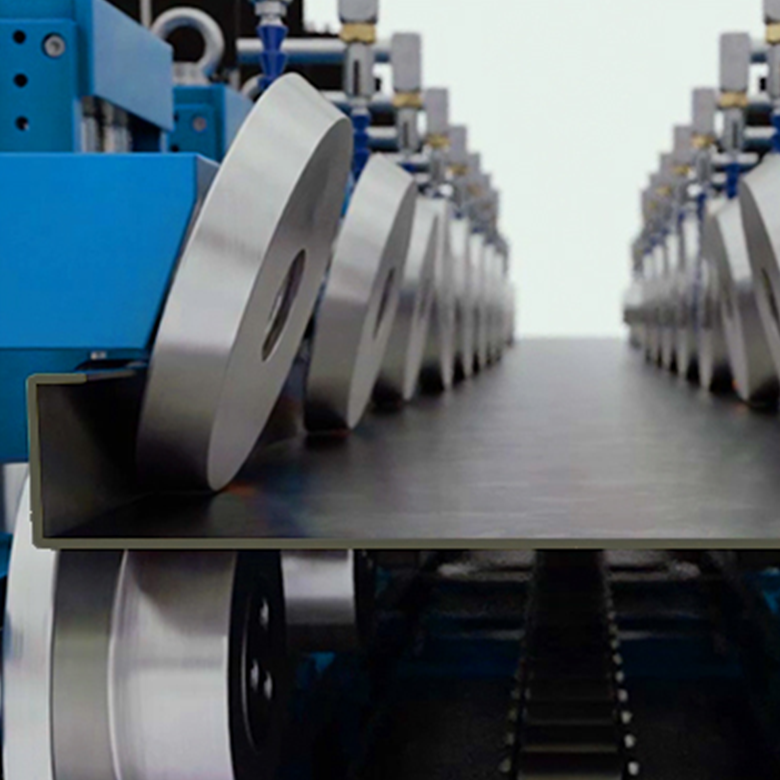

ROLL FORM LINES

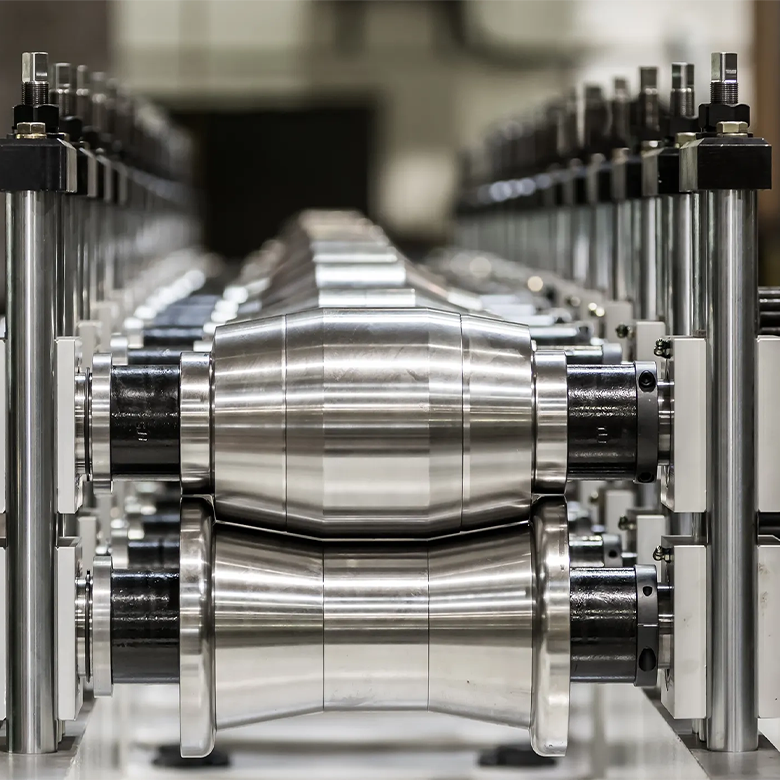

Machines designed by ESTECH combine our extensive experience and expertise, focusing on technical reliability, safety, high flexibility, and rapid tool changes according to product shape. All roll-forming machines are designed as flexible production lines, enabling waste-free and scrap-free manufacturing through advanced software and programming based on the principles of flexible manufacturing systems.

Beyond standard models, ESTECH offers custom-designed sheet metal processing lines tailored to meet specific customer needs, including:

- Lighting fixtures and reflectors

- Cable tray production lines

- Logistics warehouse shelving systems production lines

- Supermarket shelving and metal furniture systems production lines

- Electrical control panels and accessories production lines

- C, U, Z, and Sigma profile prefabricated building components production lines

- Road barrier and highway signage systems production lines

- Radiator production lines

- Agricultural and livestock industry solutions

- Home appliances and automotive industry solutions

ESTECH manufactures roll-forming lines that cater to every industry and need. The roll-forming machines are capable of performing the following operations:

- Pre-punched and notched coil sheet forming

- Post-roll forming operations, such as punching, notching, or forming with intermediate bends

- Cutting with a flying shear at the exit

- Scrap-free forming of pre-cut material

- In-line operations, including punching, welding, and cutting to length

These machine lines can produce profiles with thicknesses ranging from 0.2 mm to 6.0 mm for various industries and applications. They offer the necessary flexibility, precise forming, cutting, and production speed required for efficient manufacturing.

Cut-to-Length Line

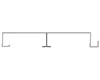

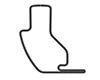

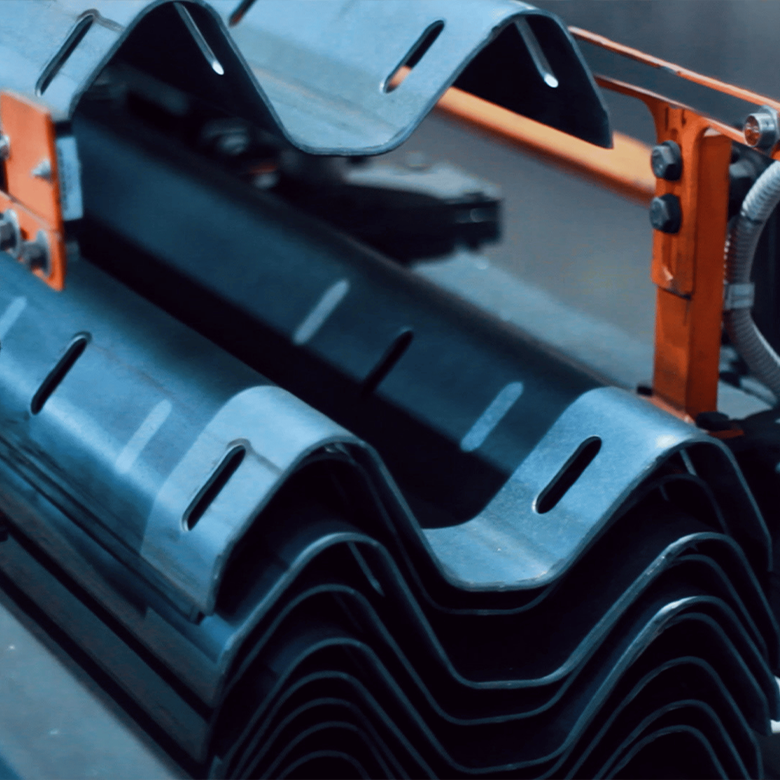

Highway Barrier Roll Forming Line

Highway barrier products can be manufactured within ESTECH designed flexible production lines. All required profiles for barriers can be produced either on different machines or on the same machine using cassette change systems. The materials used are typically grades S 275 JR, S 355 JR, and S 420 MC. The lines can operate in start-stop mode or fully automatic mode, with quick cassette change capability.

Beam A Profile Production Line:

- Sheet Width: 420, 470, 750 mm

- Sheet Thickness: 3.0 – 3.5 mm

- Profile length can be adjusted and changed.

Components:

- Decoiler

- Straightening and Welding Unit

- Feeder

- Multi-Press Group

- Roll Forming Machine

- Cassette Set for Beam A, Beam B, and Heavy Series

- Flying Shear

- End Swaging Unit

- Stacking System

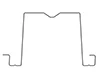

Additional Cassette Set for SIGMA (Post) Profile:

- Sheet Thickness: 4.0 – 4.5 mm

- Profile length can be adjusted and changed.

Components:

- Decoiler

- Straightening and Welding Unit

- Feeder

- Integrated End Cutting and Punching, Multi-Press Group

- Roll Forming Machine

- Cassette Set

- Flying Shear

- Stacking System

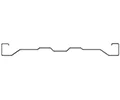

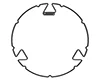

Additional Cassette Set for C (Post) Profile:

- Sheet Thickness: 4.0 – 5.0 mm

- Profile length can be adjusted and changed.

Components:

- Decoiler

- Straightening and Welding Unit

- Feeder

- Integrated End Cutting and Punching, Multi-Press Group

- Roll Forming Machine

- Cassette Set

- Flying Shear

- Stacking System

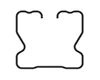

Tension Band Profile Set:

- Sheet Thickness: 5.0 mm

- Sheet Width: 70 mm

- Profile length can be adjusted and changed.

Components:

- Decoiler

- Straightening and Welding Unit

- Feeder

- Integrated End Cutting and Punching, Multi-Press Group

- Roll Forming Machine

- Cassette Set

- Flying Shear

Logistic Warehouse Shelf Production Line

FIFO and FILO Shelf System Roll Forming Line

- Quick tool changes during start-stop operations

- Sheet dimensions: 120 x 1 mm to 200 x 1.5 mm

Options:

- Embossed bearing set

- Automatic roller entry unit for cylindrical and support rollers

Roll Forming Line for Heavy-Duty Rack Systems and Silos

- Quick tool changes during start-stop operations

- Sheet dimensions: 500 mm x 3.5 mm

Options:

- Automatic clinching system

- Integrated pre-punch equipment

- Flying shear

Roll Forming Line for Light-Duty Rack Systems

- Quick tool changes during start-stop operations

- Sheet dimensions: 250 mm x 2.5 mm

- Integrated pre-punch system

Flexible Duplex Roll Forming Line for Upright Profiles

- Motorized adjustment during start-stop operations

- Quick and easy adjustment of profile width and height

- Sheet dimensions: 500 mm x 3.5 mm

- Integrated tooling with pre-punch system

Flexible Duplex Roll Forming Line for Box Beam Profiles

- Motorized adjustment during start-stop operations

- Quick and easy adjustment of profile width and height

- Sheet dimensions: 400 mm x 2.0 mm

Options:

- Box beam welding unit

- Flying shear

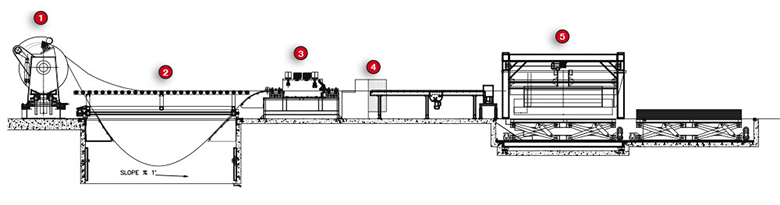

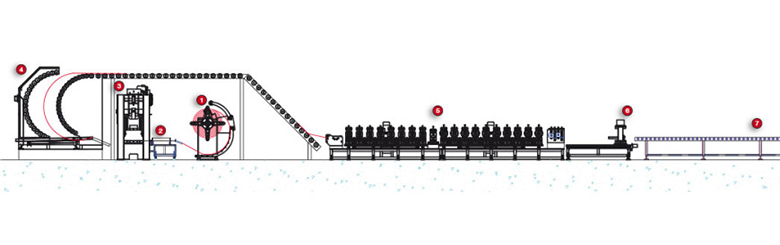

Logistic Warehouse Shelf Production Line Components:

1. Coil Decoiler

2. Coil Straightener

3. Slitting Press

4. Rear Loop Sheet Feeder

5. Duplex Roll Forming Machine

6. Flying Shear

7. Exit Conveyor

Cable Tray and Electrical Panel Production Line

Our company specializes in roll forming and processing lines for sheet metals with thicknesses ranging from 0.4 to 2.0 mm. We also provide fast solutions within the production line for speed adjustments and quick transitions between different products.

For cable trays, we offer production lines where the base width and side height are adjustable automatically, tailored to the desired production speeds. We also design production lines for electrical panels of various widths and heights. These lines can be customized based on the sheet thickness and quality, allowing for flexible manufacturing.

The production lines for cable trays and electrical panels are composed of the following components:

1. Decoiler

2. Straightening Unit

3. Feeding Unit

4. Press with Punching and Cutting Dies

5. Conveyor

6. Duplex Roll Forming Machine

7. Conveyor

8. Transfer Table

PVC Window, Drywall, and Ceiling Profiles Production Line

Machines capable of fast and high-quality production for drywall profiles are designed and manufactured by ESTECH. Drywall, ceiling, wall, and omega profiles can be automatically produced in various widths from a single machine line. The transition time between different products is very short. We offer machines capable of producing profiles in different lengths, both perforated and non-perforated.

In addition to this, our production portfolio includes lines for manufacturing window espagnolette strips and PVC support sheets for PVC window systems. We also provide specialized solutions for production from coil sheet metal.

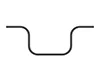

Automotive Sector Solutions

We have designed and manufactured custom Press feeding lines and Rollforming machines specifically for the automotive industry and continue to strive for even better solutions.

Many of the metal parts required for the automotive sector are produced from coil sheets, aligning perfectly with the product range of ESTECH Machinery.

Production lines have been developed for:

- Accessories and decorative products

- Structural profiles within the vehicle chassis

- Vehicle window trims

- Seat rails and plates

- Front and rear bumpers

Metal Grating and Scaffold Plank Production Line

ESTECH designs and installs advanced machine lines for metal processing across various industries, ensuring faster and higher-quality production. Among these are production lines for metal grating and scaffold planks. In response to customer demands, our R&D department at ESTECH develops innovative solutions aimed at ease of production, creating new manufacturing lines as needed. We also offer welding and part assembly solutions at the end of the line, tailored to specific applications.

Metal Grating and Scaffold Plank Production Line Components:

- Coil Decoiler

- Coil Straightener

- Electronic Coil Feeder

- Punching Press (Perforation)

- Coil Recoiler